Built-Up Roofing (BUR) for Commercial Buildings: Layers, Benefits & More

Commercial buildings require reliable, long-lasting solutions to keep operations running smoothly, especially when it comes to roofing. One of the most proven systems for flat and low-slope roofs is built-up roofing (BUR), a technique that has stood the test of time.

BUR systems have been used across commercial structures for over a century, offering resilience, multi-layered protection, and impressive waterproofing capabilities.

For facility managers and building owners evaluating roofing systems, understanding the structure, function, and application of BUR can help in making a more informed decision for long-term value.

At RN Roofing, we work with clients throughout Long Lake, MN, and surrounding areas to provide industry-backed roofing systems that meet rigorous commercial standards. Built-up roofing is more than just a layered approach—it’s a durable system designed to withstand extreme weather, foot traffic, and chemical exposure.

In this article, we’ll explore how BUR works and why it continues to be a trusted choice for commercial buildings.

Whether you're planning a new commercial roof installation or looking to upgrade from an aging system, read on to explore how built-up roofing delivers unmatched performance for commercial properties.

Understanding the Layer Structure of Built-Up Roofing Systems

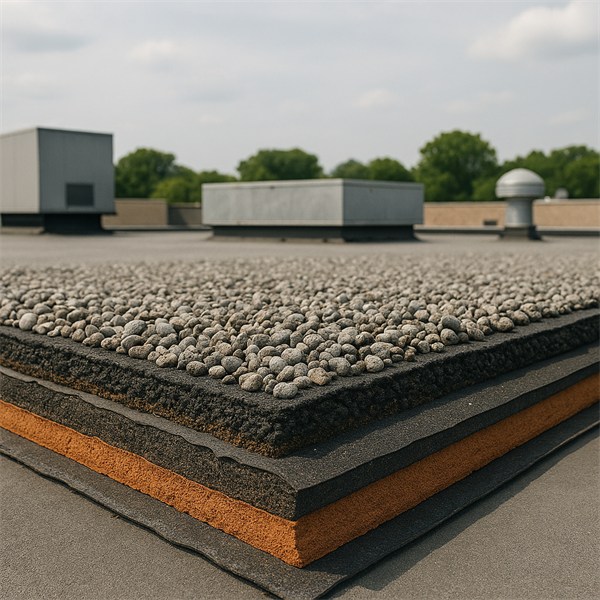

Built-up roofing (BUR) systems consist of multiple layers designed to enhance structural integrity and provide weather protection.

At the core of this design are alternating layers of bitumen (either asphalt or coal tar) and reinforcing felts or fabrics. These layers are applied in a repeated sequence, typically in three to five plies, though more may be used depending on the building’s specifications, location, or exposure to environmental conditions.

Each ply serves to enhance tensile strength, impact resistance, and waterproofing, contributing to a thicker, more durable membrane than most single-layer alternatives.

How BUR Is Constructed

The construction starts with a base sheet that is usually mechanically attached to the roof substrate. Then, alternating layers of bitumen and ply sheets are added, forming a composite membrane that provides redundancy—if one layer is compromised, others remain to protect the roof.

These layers are typically finished with a protective surfacing layer such as gravel, slag, or a reflective cap sheet. This final layer enhances UV resistance, prevents weather damage, and extends the service life of the roof.

Built-up roofing is favored for its robust, time-tested performance on low-slope commercial roofs. The multi-layer approach is integral to its durability, making it ideal for buildings exposed to high traffic or severe weather.

The Function & Importance of Gravel or Ballast in BUR

The top layer of a BUR system often consists of gravel or ballast, which plays multiple critical roles beyond just surface appearance.

The gravel is embedded into a final layer of hot bitumen while it is still tacky, forming a protective shield. This gravel surfacing provides essential UV protection, preventing the bitumen from degrading under prolonged sun exposure.

Without it, the roofing material could harden and crack, compromising the system’s longevity and waterproofing capability.

Ballast also offers significant protection against foot traffic, hail, and flying debris. For commercial buildings that house HVAC units or require routine maintenance access, gravel acts as a buffer that prevents punctures and damage to the underlying membrane.

Additionally, the ballast helps weigh the system down, improving wind uplift resistance—an especially important feature in areas with high wind exposure or taller structures with more suction pressure along the roof edges and corners.

In colder climates, gravel can help moderate temperature fluctuations on the roof surface, reducing thermal stress that leads to cracks.

As a result, RN Roofing incorporates this critical layer into BUR designs to enhance durability and protect commercial assets.

Key Differences Between BUR & Single-Ply Roofing Systems

Built-up roofing and single-ply systems represent two fundamentally different approaches to low-slope commercial roofing.

BUR systems are composed of multiple layers of reinforcing fabric embedded in bitumen, forming a thick, redundant barrier. This layered construction provides exceptional resistance to water infiltration and mechanical damage.

In contrast, single-ply membranes—such as TPO, EPDM, or PVC—are composed of a single layer of synthetic material, often adhered or mechanically fastened to the substrate.

The Redundancy Matters

One of the primary distinctions is in redundancy. BUR offers built-in protection through its multi-layer design, meaning that a breach in one layer does not necessarily lead to immediate failure.

Single-ply membranes, while often faster and cleaner to install, rely entirely on the integrity of that single layer.

This makes BUR a preferred option for buildings requiring enhanced durability and waterproofing redundancy over decades of performance.

Robustness in Harsh Conditions

Cost, installation time, and energy efficiency also differ. Single-ply systems may offer better reflectivity and quicker installation, while BUR provides unmatched robustness in harsh conditions.

Decision-making often depends on project-specific needs, but understanding these distinctions helps commercial property owners select the right system for long-term value.

Waterproofing Advantages of Built-Up Roofing

One of the standout benefits of BUR systems is their superior waterproofing capability. The layered design forms a nearly impermeable barrier, reducing the risk of leaks even under standing water.

Each ply embedded in bitumen contributes to a watertight seal that self-heals to a degree under heat, effectively sealing minor punctures or cracks over time. This makes BUR one of the most dependable systems for waterproofing in areas prone to heavy rain or snowmelt.

The top gravel or reflective surfacing further protects the membrane from UV degradation and erosion caused by freeze-thaw cycles. This surface layer also acts as a buffer to reduce the thermal movement that can stress roof membranes. Over time, these benefits help extend the lifespan of the roof and maintain waterproofing integrity without frequent maintenance or replacements.

Given the scale of commercial buildings and the potential cost of water intrusion, choosing a system like BUR—installed by experienced professionals like RN Roofing—can deliver years of leak-free protection backed by industry knowledge and craftsmanship.

Industries That Commonly Use Built-Up Roofing Systems

Built-up roofing is extensively used across a wide range of commercial industries due to its performance in demanding environments.

Sectors with large, flat roofing footprints—such as manufacturing, warehousing, retail, and government—often rely on BUR systems to protect their facilities.

These buildings typically require roofs that can withstand continuous exposure to equipment vibrations, temperature fluctuations, and foot traffic from maintenance personnel.

Healthcare facilities, schools, and universities also frequently opt for BUR systems due to the need for low-maintenance and fire-resistant solutions.

In public buildings or institutional settings where roof access is common and long-term budget planning is critical, the proven lifespan and durability of BUR systems offer a strong return on investment.

Their resistance to chemicals and mechanical damage makes them especially suitable for labs, processing plants, and industrial complexes.

Commercial real estate developers and large property management firms often choose BUR for its track record.

Its performance in cold and hot climates, as well as its resistance to wind uplift and water intrusion, has made it a mainstay in commercial roofing portfolios across the Midwest and beyond.

Get Expert Help with Built-Up Roofing from RN Roofing

Whether you're assessing the ideal number of protective layers, understanding the role of gravel in your system, comparing BUR to single-ply membranes, identifying where BUR is most applicable, or evaluating waterproofing solutions, RN Roofing can help you navigate each step with precision and expertise.

RN Roofing has built a reputation for excellence across commercial roofing services. Our team specializes in evaluating, installing, and maintaining BUR systems tailored to meet the unique demands of industrial, institutional, and commercial buildings.

With an in-depth understanding of the performance expectations across multiple industries, they deliver solutions that stand up to time, weather, and use.

If you're ready to explore how a BUR system can strengthen your facility’s roofing infrastructure, contact RN Roofing at 952-334-3702 or request a free estimate today. Our experienced team will help ensure your roofing system meets the highest standards for protection and performance.